Search

Search

Recent years have seen significant changes in consumer expectations for goods and services. Amazon and similar companies have developed and implemented an unprecedented order-to-delivery business model that has led to a shift in consumer demand. Add to this the strains that COVID-19 and other pressures, including geopolitical, operational, regulatory, financial, and security, on the global supply chain have caused, we now live in a world where the complexities and opportunities of consumers’ demands and the expectation that companies will be able to fulfill their needs at a moment’s notice can come into hard contact with the strains of real-world supply chain issues.

Consumers want more and faster—yet real-world circumstances can dictate the opposite. For companies to thrive, or even survive in today’s market, they must design and implement a holistic approach to supply chain management that focuses—delivering both simultaneously and across the enterprise—on resiliency, optimization, sustainability, and risk management.

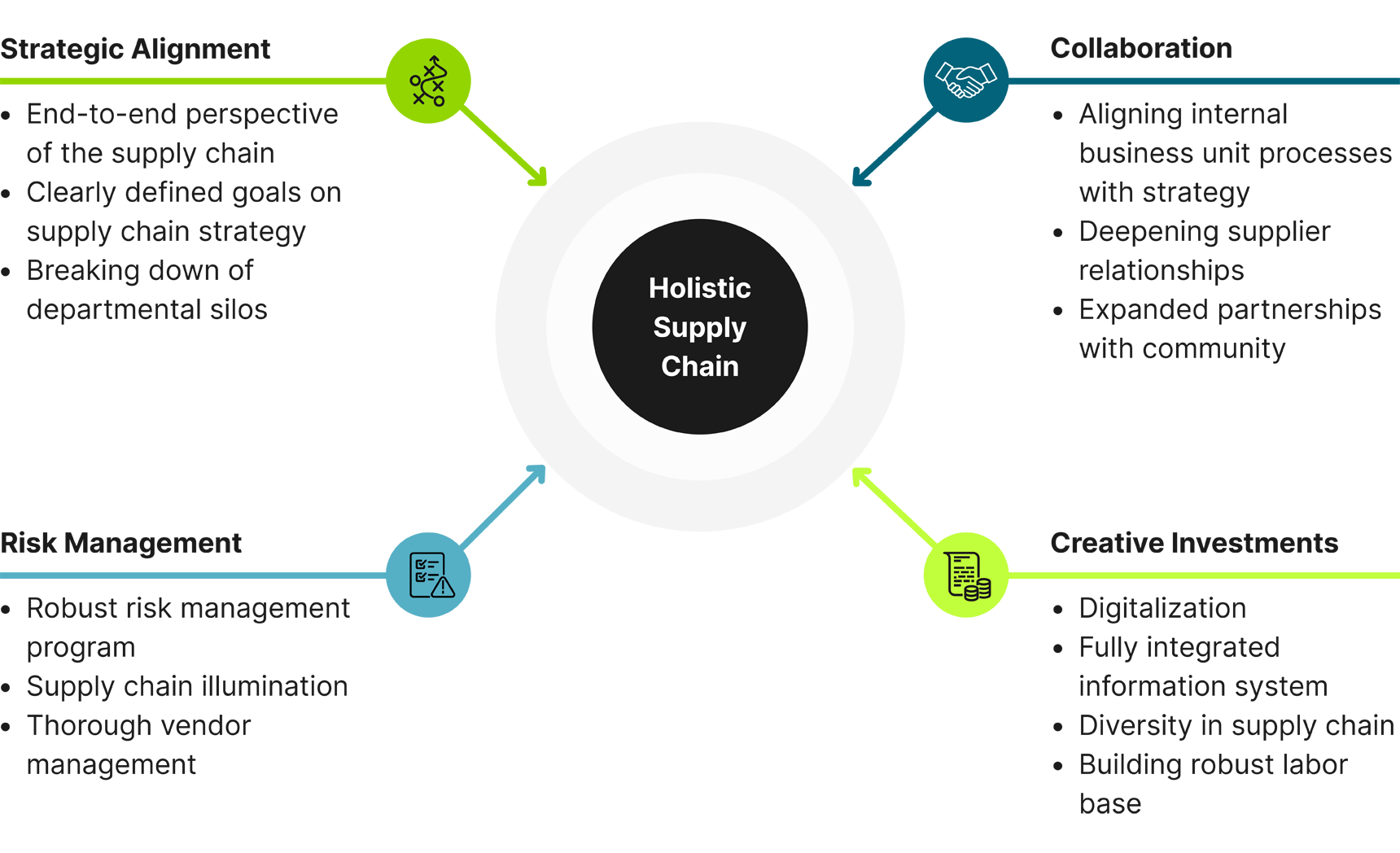

A holistic supply chain connects the various supply chain components, internal and external, to achieve seamless, end-to-end operations. Traditional supply chain concepts often look at the impact that the flow of goods and services, data, and finances have on a singular business. A holistic supply chain, by contrast, considers these same concepts through the lens of how that business impacts and is impacted by the world around it. This is achieved by focusing on the following priorities in concert with one another:

In an ongoing example that involves SCRM, regulators and others are investigating AOG Technics, a UK-based broker founded in 2015. According to CFM International,1 AOG Technics allegedly sold counterfeit aircraft engine parts and other parts of unknown origin to major airlines (including American, Delta, Southwest, etc.) by using false documentation. The investigation, led by the UK’s Serious Fraud Office, has grown to include other authorities too, such as the U.S. Department of Justice, and has seen raids and at least one arrest. Meanwhile, SCRM analysts are focused on how this could have occurred, its origins, potentially missed warning signs, and how dangerous fraud schemes like it can be prevented in the future as it demonstrates that all industries and even the most mature organizations are at risk.

Leveraging these priorities—resilience, optimization, sustainability, and SCRM—can lead organizations to assess topics outlined below, such as strategic alignment, collaboration, risk management, and creative investments, on their path toward a holistic supply chain. This may also include reviewing situational awareness, connectivity with third parties, competitiveness, opportunities, risks, preparedness, and more.

Understanding and leveraging these elements of your supply chain can position you better than your competitors by making your organization leaner, more prepared, more focused on data and intelligence-driven decisions, and more strategic when it comes to looking for opportunities to exploit and risks to mitigate. Having these ingredients positions your organization for speed, accuracy, enormous growth, situational awareness, and so much more.

Exploring and even implementing some of the following activities can start an organization on a path to a mature and holistic supply chain capability:

Companies looking to create this transformation to a holistic supply chain can potentially feel overwhelmed by the monumental task of building the team with the experience and knowledge to succeed while leveraging the data sources, technologies, tools, and more for this new environment — and doing so while every dollar that goes to non-revenue producing activities is understandably scrutinized. Below are some of the challenges:

For example, there are increasing regulations coming into effect related to Chinese semiconductors2 and their use in goods and services for the U.S. government and those that sell products and services to it. If you are a producer of just about anything and you are not aware of and heeding these and other regulations and prohibitions, there is a good chance your company will get crossways now or in the future, no matter who your clients are in the United States, because you or they will want to sell to the U.S. government.

Why Guidehouse?

Maintaining the integrity of the supply chain and logistics operations while evolving to address new sustainability, security, and resiliency demands requires a different approach with modern solutions to navigate forward.

Guidehouse is a leading global provider of consulting services to the public sector and commercial markets, with broad capabilities in management, technology, risk consulting and a comprehensive suite of digital services. By combining our public and private sector expertise, we help clients address their most complex challenges and navigate significant regulatory pressures focusing on transformational change, business resiliency, and technology-driven innovation. Across a range of advisory, consulting, outsourcing, and digital services, we can help our clients find scalable, innovative solutions to outwit complexity and position them for future growth and success.

Guidehouse is a global AI-led professional services firm delivering advisory, technology, and managed services to the commercial and government sectors. With an integrated business technology approach, Guidehouse drives efficiency and resilience in the healthcare, financial services, energy, infrastructure, and national security markets.